Industry 4.0 is often described as the fourth industrial revolution — a phase defined by connected machines, intelligent automation and real-time data exchange. But from our perspective at Cirmar, its essence is simpler and more practical. Industry 4.0 is about making life easier for companies. It does this by making data available, interoperable and exchangeable under clear and shared rules.

In Europe, this evolution is entering a new phase. The focus is shifting from operational efficiency toward material intelligence and circularity. The European Green Deal, the Circular Economy Action Plan, and most recently the Ecodesign for Sustainable Products Regulation (ESPR) are not just regulatory milestones — they signal a structural transformation in how products are designed, documented and recovered. At the centre of this shift stands the Digital Product Passport.

If Industry 4.0 connected machines and processes, DPP 4.0 connects materials and use cycles.

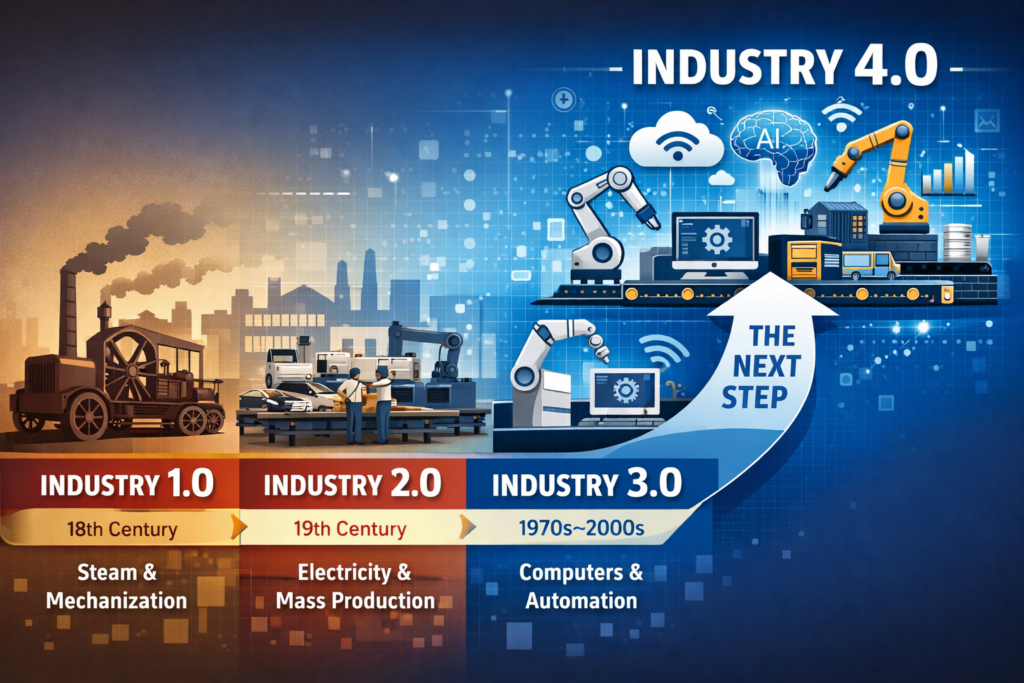

AI was used to generate this image – and it will do a lot more in Industry 4.0…

European policy takes twists and turns, but the finish line is clear: products placed on the EU market must become more sustainable, more transparent and more circular. The ESPR introduces the Digital Product Passport as a key instrument to achieve this. It requires structured, standardised product information that can be shared across the value chain — from manufacturers and importers to repairers, recyclers and consumers.

This is not simply a compliance exercise. It is the creation of a common data infrastructure for materials in Europe.

For decades, product data has been fragmented across systems and organisations. Bills of materials, safety data sheets, technical documentation and recycling instructions often exist, but rarely in a harmonised, machine-readable format that can travel with the product. The Digital Product Passport changes that paradigm. It turns product documentation into structured, interoperable data that persists throughout the use cycle.

In this sense, DPP 4.0 represents the natural continuation of Industry 4.0 within the regulatory and economic framework of the European Union.

For Digital Product Passports to function effectively across Europe’s single market, they must be embedded in existing data ecosystems. They cannot become isolated reporting tools. Interoperability and standardisation are essential.

At Cirmar, we focus on building this connective layer. Our platform aligns DPP information with globally recognised product identifiers and standardised product data structures. This alignment is critical in a European context where cross-border trade and supply cycles demand harmonised information flows.

Beyond external standards, we are working on deep integrations with our users’ Product Information Management (PIM) and Enterprise Resource Planning (ERP) systems. By connecting the DPP directly to internal data sources, we reduce duplication, minimise manual reporting and ensure consistency. The Digital Product Passport becomes part of the operational backbone rather than an administrative add-on.

Industry 4.0 established system connectivity. DPP 4.0 extends this connectivity to regulatory-grade material transparency.

One of the major practical challenges in implementing Digital Product Passports — particularly in complex European supply chains — is incomplete or inconsistent material data. Many companies do not have full visibility over the exact material compositions of their products, especially where legacy products or multi-tier suppliers are involved.

Artificial intelligence plays a crucial role in overcoming this barrier.

At Cirmar, we already apply AI to uncover material compositions where data is incomplete. By analysing available specifications, documentation and comparable datasets, our system helps reconstruct material insights that might otherwise remain inaccessible. This significantly lowers the threshold for companies preparing for upcoming DPP obligations under the ESPR.

At the same time, Europe’s circular economy ambitions require more than transparency about virgin materials. They demand clarity about recovered and secondary materials as well. We are therefore developing AI-powered characterisation tools for recovered materials, combined with a uniform nomenclature system (have a look at our project website – Reïnkarneer). Standardised terminology is essential if secondary raw materials are to circulate efficiently within the European market. Without shared definitions and structured descriptions, materials cannot be reliably traded, reused or integrated into new production cycles.

By recording this harmonised material intelligence directly within the Digital Product Passport, we create the foundation for functioning secondary material markets.

Industry 4.0 demonstrated the value of data availability and rapid exchange. However, the more important consequence of these developments is the insight they enable. When product and material data become structured, connected and accessible across actors, entirely new possibilities emerge.

Companies can understand precisely what materials are embedded in their products. They can design with recovery in mind. They can plan disassembly processes based on real data rather than assumptions. Recyclers gain clarity about input streams. Manufacturers gain confidence in secondary material quality. Policymakers gain traceable information to measure progress toward sustainability targets.

In Europe’s regulatory environment, this shift is not optional. It is becoming the operating model for sustainable industry.

Digital Product Passports transform Industry 4.0 from an efficiency revolution into a circular economy infrastructure.

While regulatory drivers such as the ESPR and related delegated acts create urgency, the real opportunity lies in strategic positioning. Companies that treat the DPP merely as a compliance task will capture only part of its value. Those who integrate it into their digital strategy gain deeper material insight, stronger supply chain resilience and access to emerging secondary material markets.

Europe’s competitiveness increasingly depends on resource security. Critical raw materials, supply chain dependencies and climate targets all point in the same direction: materials must remain in circulation longer and at higher value. Digital Product Passports provide the data backbone to achieve this.

At Cirmar, we see our role as building this backbone. Through AI-driven material analysis, harmonised nomenclature for recovered materials, and seamless integrations with established data infrastructures such as GS1, as well as PIM and ERP systems, we are helping to connect Europe’s fragmented material data landscape.

Industry 4.0 connected factories.

DPP 4.0 connects materials across use cycles.

Together, they form the infrastructure for a waste-free, circular economy — one where products are not endpoints, but temporary configurations of valuable resources.

That is the transformation Europe is moving toward. And it is the transformation we are building for, every day at Cirmar.