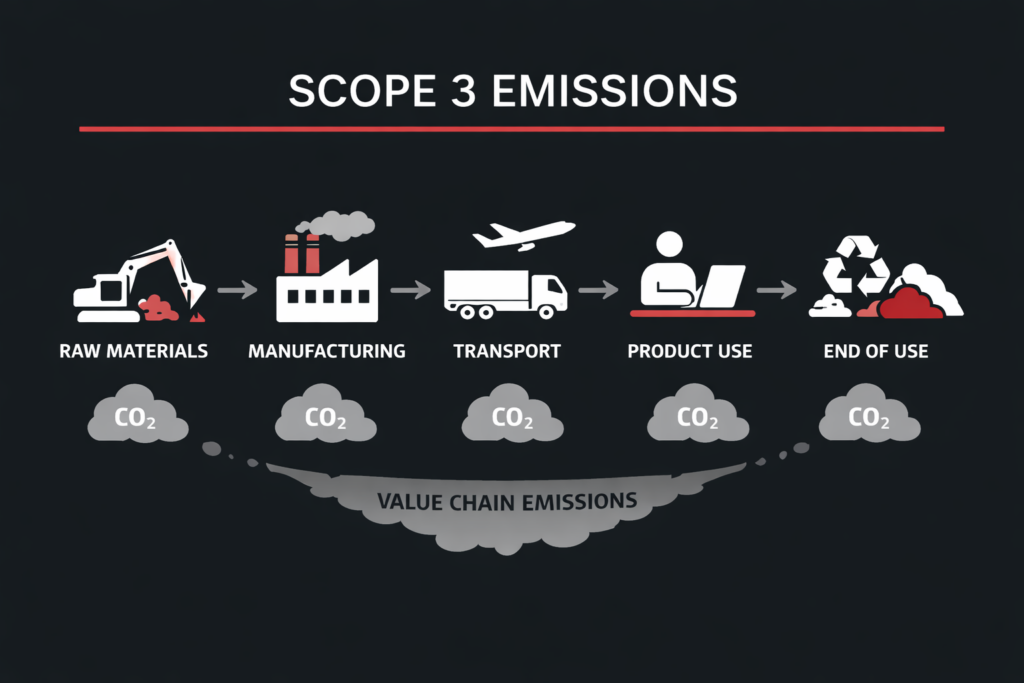

Reducing greenhouse gas emissions has become a strategic priority for companies across all sectors. While Scope 1 and Scope 2 emissions are increasingly well understood and managed, Scope 3 emissions under the GHG Protocol remain the most complex and the most material. For many organisations, Scope 3 accounts for the majority of total emissions, as it covers impacts generated throughout the value chain, from raw material extraction and manufacturing to product use and end-of-life treatment. This complexity often leads to uncertainty, approximations, and missed opportunities for real reduction.

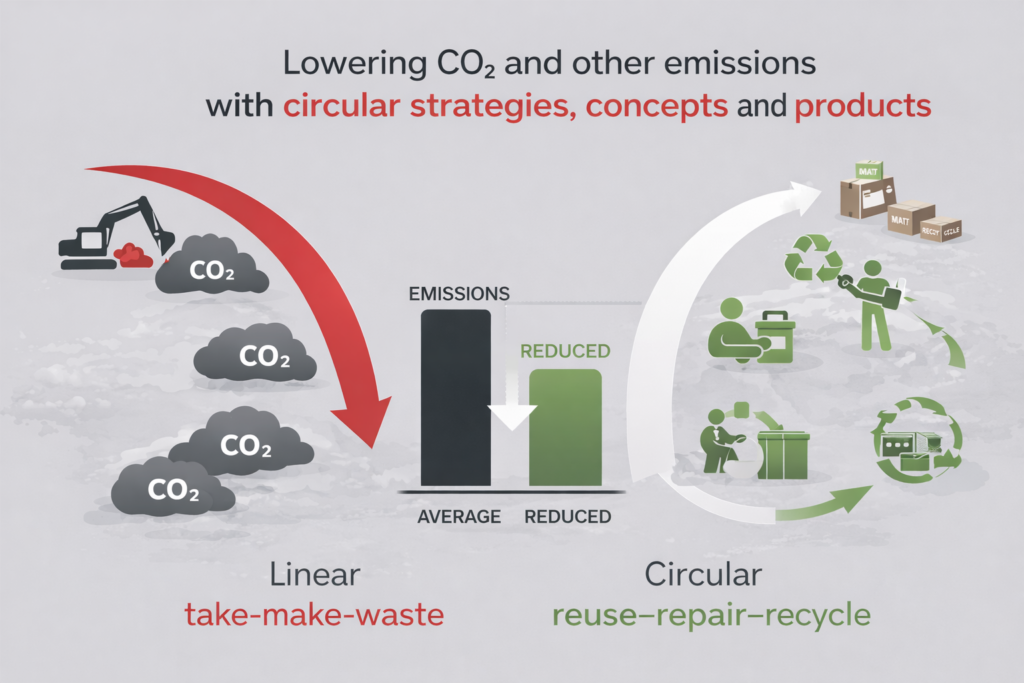

At the same time, circularity is gaining momentum as a core sustainability strategy. Circular business models aim to keep materials in use for as long as possible, reduce the need for virgin resources, and minimise waste. However, circularity only delivers climate benefits when it can be translated into quantifiable reductions in Scope 3 emissions. Without reliable data at product and material level, circular ambitions remain difficult to validate, compare, and scale.

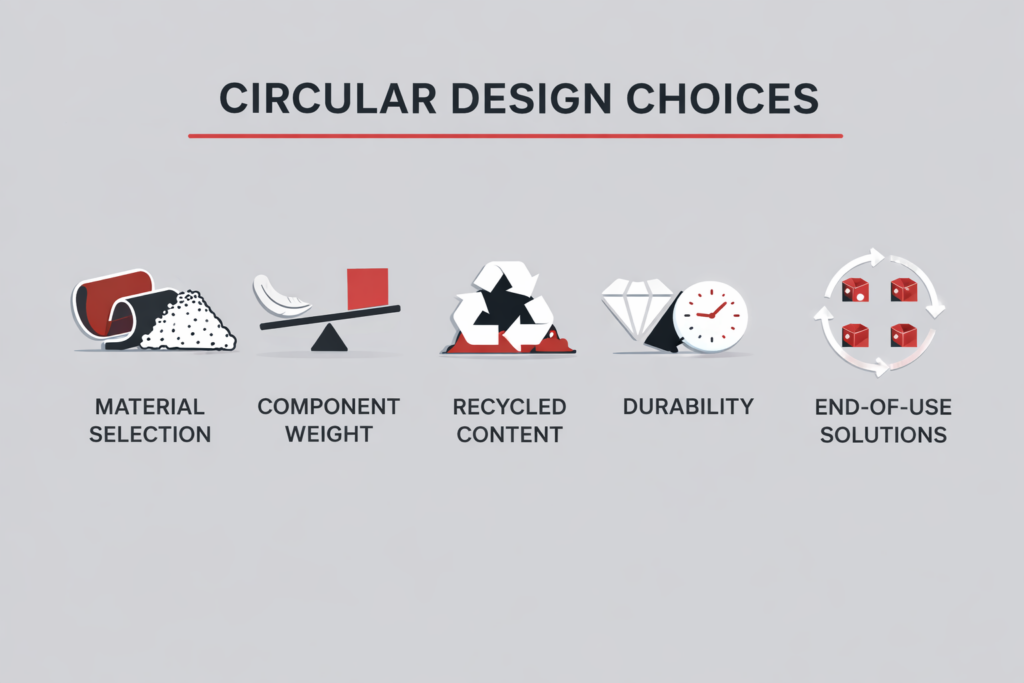

Scope 3 emissions are fundamentally driven by the materials used in products, how those products are designed, and what happens to them at the end of their life. Decisions such as material selection, component weight, recycled content, durability, and end-of-use solutions directly influence emissions across the entire lifecycle. A linear design typically leads to higher emissions due to repeated extraction of virgin materials and limited recovery at end of life. In contrast, circular design strategies such as reuse, refurbishment, remanufacturing, and high-quality recycling can significantly lower value-chain emissions.

Despite this strong connection, many Scope 3 calculations still rely on spend-based or average emission factors. These approaches may be suitable for high-level reporting, but they lack the precision needed to assess circularity strategies or guide product-level improvements. As regulatory requirements such as CSRD and market expectations continue to increase, companies need granular, product-specific data to understand where emissions occur and how they can be reduced.

At Cirmar, we believe that meaningful Scope 3 reduction starts with understanding products at their core. This means moving beyond generic assumptions and focusing on the actual composition of products, components, and materials. By combining detailed product data with lifecycle thinking, Scope 3 emissions can be calculated in a way that reflects real design and sourcing choices.

Cirmar’s C_passport® enables automated impact calculations based on material composition, weight, and defined end-of-use scenarios. This approach allows companies to calculate environmental impacts across different lifecycle boundaries, including cradle-to-gate, cradle-to-grave, and cradle-to-cradle (LCA+). As a result, Scope 3 emissions are no longer abstract estimates, but measurable outcomes linked directly to product design and circular strategies.

Accurate Scope 3 calculations only create value when they support better decisions. C_passport® translates product and material data into clear, actionable key performance indicators that connect circularity with climate impact. Companies can quantify CO₂ emissions across lifecycle stages, assess energy and water impacts, and measure the amount of materials saved through circular design and recovery strategies. In addition, emissions can be expressed in financial terms through a CO₂ price aligned with the EU Emissions Trading System, helping organisations understand the economic implications of their sustainability choices.

By using consistent and automated calculations, companies can compare design alternatives, evaluate suppliers, and assess the impact of circular interventions over time. This creates a strong foundation not only for Scope 3 reporting, but also for continuous improvement and innovation.

Scope 3 reporting should not be treated as a compliance exercise alone. When linked to circularity, it becomes a powerful tool for reducing emissions at their source. Product-level insights enable companies to redesign products, optimise material use, and choose end-of-life solutions that keep value in the system while lowering environmental impact. Over time, this leads to structurally lower emissions, reduced exposure to carbon pricing, and increased resilience in a resource-constrained economy.

Cirmar’s approach is built around this transition from reporting to improvement. By embedding impact calculations into product data, C_passport® supports companies in turning sustainability goals into measurable action.

Understanding and managing Scope 3 emissions is one of the biggest challenges companies face today, but it is also one of the biggest opportunities. Circularity provides the strategy, and data provides the proof. With C_passport®, companies can start calculating Scope 3 emissions at product, component, and material level, and more importantly, use those insights to improve circularity and achieve lasting emission reductions.

Now is the time to move beyond averages and assumptions. Give C_passport® a go and take concrete steps towards measurable circularity and lower Scope 3 emissions across your value chain.