We hosted a joint webinar with Cibutex and bAwear, to discuss the opportunities of transitioning to more circular practices for B2B textiles. Our combined efforts started with a pilot use case for circular kitchen towels, which will be followed by other products in the near future. In this article, we’ll point out the our most important conclusions and next steps, and you can rewatch the full webinar.

Among the many European legislative initiatives concerning sustainable products, B2B products are sometimes overlooked. Lots of legislation is aimed at helping consumers make more sustainable choices, or to allow them to use more sustainable products. Textiles in particular is one of the product categories that is increasingly regulated, for example through the regulation of waste shipments, the Ecodesign for Sustainable Products Regulation, or the CSRD. All of them are important steps to realise more circular textiles, but Cibutex has identified a specific opportunity for B2B textiles.

Cibutex focuses on B2B textiles for a few simple reasons. Firstly, these products are usually consistent and relatively simple in composition. This makes them ideal for recycling, as well as improvements that increase their circularity. Additionally, they come in predictable, traceable volumes: we know what products are used and where. That makes it much easier to organise reverse logistics, partner up with recyclers to create the necessary feedstock for their processes, and to identify markets for next use. The volumes used are also concentrated on a limited number of locations. For B2C textiles, this is a different story, as it is usually difficult to track products after they are sold. Last but not least, B2B textiles are often already handled by textile service companies, which are used to work as efficiently as possible. This in turn also helps implement product improvements, as these companies handle large quantities and have lots of knowledge about the ideal treatment of the various fabrics that are used.

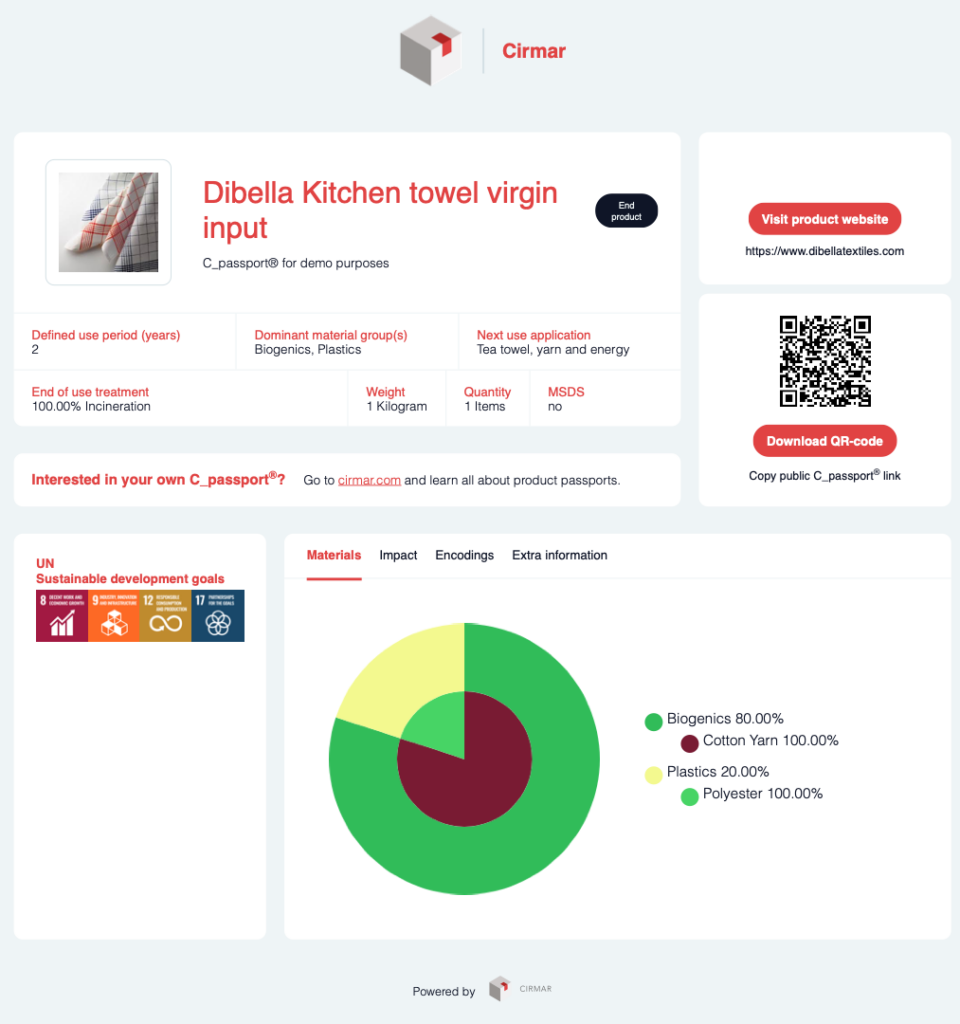

We couldn’t agree more with Cibutex: B2B is a great place to start improving products towards circularity. One of the key tools to realise this sustainable progress is the implementation of digital product passports like C_passport®. If we can better design products for circularity, and find reverse logistics partners as well as recyclers, everything seems to be set for a circular product. However, if we fail to record the information needed for all supply chain partners to realise this circular potential, it might be lost. Digital product passports allow companies to record valuable information like material composition, recycling and next use instructions, as well as impact data and connect all of this to a physical product. And as the demand for better and more complete product data increases, they are quickly becoming a license to operate in many markets.

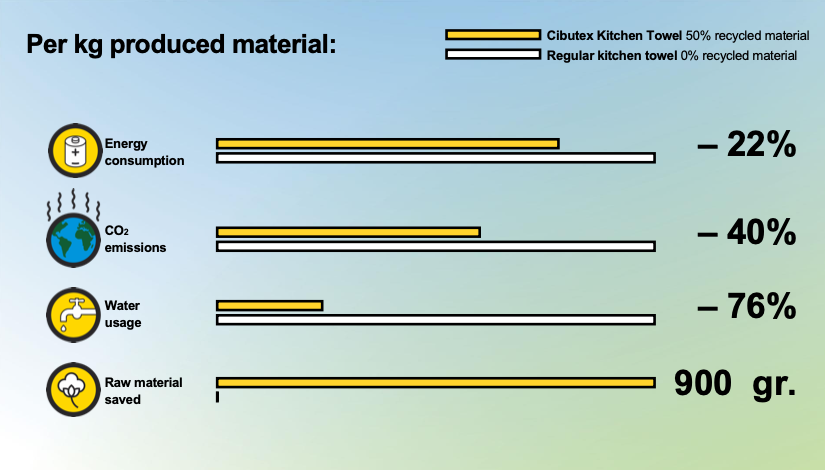

For many products, material use is the dominant factor in determining a products footprint. Especially for circular products, it makes all the difference that materials are recuperated. This avoids new sourcing and results in a significantly lower footprint than competing, linear products. For B2B textiles however, we need to dig a little deeper to fully understand the impact of products, which is why we were happy to join forces with bAwear for this pilot project. They perform streamlined LCA’s for textile products, calculating with a cradle-to-grave scope. Our combined inputs allowed us to calculate in detail what the ideal composition of a kitchen towel is, given that it will be washed and used extensively. As a result, we can determine the upside of circular progress within this pilot project, as illustrated in the figures below.

That’s good news. We happily invite anyone active in B2B textiles to join the Cibutex initiative. They can make pilot projects happen, and expand them to the point where they are fully integrated in day to day business. If the impact calculations and the creation of digital product passports is of interested to you as well, we have an offer: come to us with a bill of materials of a product. Together with bAwear, we will generate the first digital product passports accompanied by impact data for free. Sometimes you simply have to see what we can already do with the available technology to understand its added value.