The next generation of talent will play an important role in shaping the future of the circular economy. As a company specialising in Digital Product Passports (DPPs) and circularity consulting, we regularly collaborate with circular economy students to tackle real-world challenges. One such collaboration involved our colleague Frans guiding chemistry students Sefika and Bintu in an ambitious project focused on plastic recycling and product improvement.

Sefika and Bintu’s project revolved around an everyday yet complex product—a plastic bucket. Specifically, the aim was to improve a bucket made entirely of recycled plastic, except for its lids and handles, which were still made from virgin polypropylene (PP). The reason? The recycled materials weren’t strong enough, especially for stacking purposes.

The company – Dijkstra Plastics – had already sourced granulate with unknown additives, but the lids remained a weak point. Sefika and Bintu’s challenge was clear: can we strengthen the lids using the same recycled granulate, without resorting to virgin material?

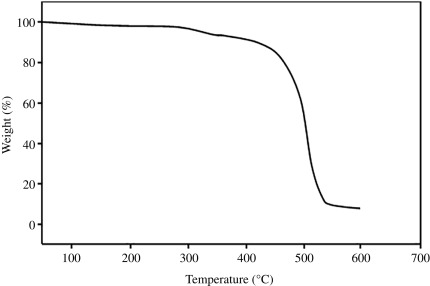

Through a series of chemical tests and structural analyses, the students explored ways to close the plastic loop effectively. They discovered that minor contaminations—like mixing PP with just 5-10% polyethylene (PE)—significantly weakened the material. Repeated recycling cycles further degraded thermal stability, creating additional barriers to product strength and longevity.

“We got to try out new reactions and experiment with different methods, which made the project very hands-on. It was exciting to apply what we’ve learned in a real setting and see actual results from our ideas” – Bintu

Thermal stability explained:

Thermal stability is a material’s ability to maintain its properties when exposed to heat. In plastics, this means the material won’t easily weaken, deform, or break down when recycled or reused at high temperatures. Each recycling cycle exposes plastic to heat, which can damage its structure, making it less strong or brittle. This is a key challenge in the circular economy: if a material loses stability after multiple recycling rounds, it can’t be reused effectively. Enhancing thermal stability helps materials stay durable longer, supporting better recycling processes and reducing the need for virgin materials.

One of the project’s biggest revelations was just how complex plastic circularity can be. Sefika explains, “We found that even small contaminants make a big difference. You also need to know exactly what you’re working with, but that information isn’t always available.”

The research delved into the porosity of plastics—critical when buckets previously held materials like paint, which seeps into microscopic pores. Sefika and Bintu tested various chemical treatments to reduce pore formation, enhancing the material’s durability.

“It’s not just about adding a chemical,” Sefika shares, “but about understanding the entire lifecycle of the material, from collection to reprocessing. Without clean, separated streams, the circular system struggles to function.”

The students’ visit to Dijkstra Plastics translated their academical knowledge to real-life applications. Observing large-scale testing and logistics provided real-world insights that lab settings couldn’t replicate. “Seeing their process made it clear where breakdowns happen and how each party in the supply cycle plays a role,” Sefika notes.

This experience underscored that without alignment across the supply cycle—cleaners, recyclers, manufacturers—circular economy ambitions stall. For Bintu, combining all factors that are involved in circular progress was a valuable lesson: “It’s not just science. You need to understand business, design, regulations, and how products are actually used.”

Throughout the project, Frans from Cirmar offered guidance on circular strategies already underway and data-driven approaches to material management. His mentorship helped the students not only in technical exploration but also in contextualising their findings within broader industry trends.

“Frans showed us how data is essential for circular decision-making,” Sefika reflects. “It’s not enough to just recycle; you need traceability and transparency, which is what Cirmar’s DPPs enable.”

Sefika, currently a Bachelor of Chemistry student, sees this experience as a launchpad. “I want to dive deeper into polymers. They are simple in theory but so complex in practice—it’s fascinating!”

The complexity of sustainable, circular progress requires a lot of expertise. As the students found out, that expertise is not restricted to recycling technologies. Bintu does see herself continue her learning path in the field of sustainability and has good reasons for doing so: “It’s hard to ignore the direction the world is heading in when it comes to the environment. As a chemistry student, I feel like I have the chance to be a part of the solution. If I can use my skills to contribute even in a small way, that’s something I want to do.”

If there’s one key takeaway from the project, it’s that the circular economy is a systems challenge. As Sefika and Bintu discovered, governmental and corporate efforts are often tangled in complexity. True progress requires collaboration, data transparency, and continuous research.

Cirmar offers Digital Product Passports as a Service and expert consultancy to accelerate the transition to a circular economy. Through partnerships with educational institutions, we aim to foster the skills and knowledge needed to build a truly circular world.